MAKEREADY

Makeready is the process of making all parts of the form print correctly.

A form of heavy and light elements mixed, even after having been leveled

in lockup, will be found to require varying degrees of impression to

print well. Dot leaders, fine type, and rules may be printing too heavily

while large type and solids are too light. Makeready selectively increases

and reduces the impression where required.

Even at the stone, heavy elements anticipated to require additional

impression can be underlaid with tissue or manifold paper, held to the back

of the form with a spot of grease; and for some jobs, this will be enough.

A dab of grease can be left on the frame of the press for this purpose.

It is possible, in the case of photopolymer plates taped to metal blocks,

to interlay the plate—that is, to use two layers of tape on heavy parts

of the plate, or to omit tape from light parts, to create a difference in

impression. But the chief method of makeready is the overlay.

The Overlay . . .

The position of the sheet having been determined, the packing is adjusted

to produce a light even impression over the whole form, so that the light

parts of the form seem to be printing more or less as they should be on

the stock intended for the job. A

rule or leader that is punching can be dealt with later.

The packing should contain a draw sheet held in place with the tympan under

the bottom bail, and a loose sheet of paper in with the other packing

as well.

The Spot Sheet

Now an impression is pulled on a piece of bond paper or somesuch. This

sheet is held in position against the packing in the guides, and stabbed

through into the packing in a couple of places with the makeready knife.

Two short horizontal

cuts along the top edge of the sheet, apart from each other, each intersected

with a vertical cut into the sheet work well. The idea is to be able to

position the bond “spot” sheet under the packing,

taped to the draw sheet

in exact register with the form. Now, those areas of the form requiring

additional impression may be pasted up on the spot sheet with pieces of

tissue or manifold. (The printer should keep an eye out for suitable thin,

hard, even papers and collect them. I have been using the paper from

corporate proxy statements. “Yes” paste, from your art supply

store works well.) Leaders and areas that are punching may be cut away in

the spot sheet or sanded down. (If cut only on three sides and folded out

of the printing area, these flaps may be folded back in place if need be.)

The stab marks are aligned and the spot sheet taped in position

to the draw sheet under the tympan; the loose sheet is removed,

so that the overall thickness of the packing is

unchanged by the addition of the spot sheet. Another impression is pulled,

and additional spotting up done if needed. Observations:

- Some pressmen use two sheets of carbonless paper under the tympan, so

that pulling an impression leaves a marked sheet in place in the

packing.

- Some pressmen pull an impression on the packing and tape over the weak

parts. This method is likely to interfere with feeding on the handfeed

and to shorten the useful life of the tympan. It does not permit of

refinements.

- A spot sheet close to the tympan will have a more specific effect on

the printing than one buried in the packing more deeply by covering it

with other packing material. Something to play with.

- I have sometimes used pieces of latex rubber dental dam under the

tympan on especially

heavy areas or areas intended to show deep impression.

- The spot, cut makeready sheet can often been saved for reuse.

Sometimes the entire packing can be stored for repeats.

- On a cylinder press, the press is stopped before the spot sheet (or

envelope) leaves the gripper, and stabbed through in position.

- Makeready and register are the duties of the press operator. To

check register, put several sheets through the press twice.

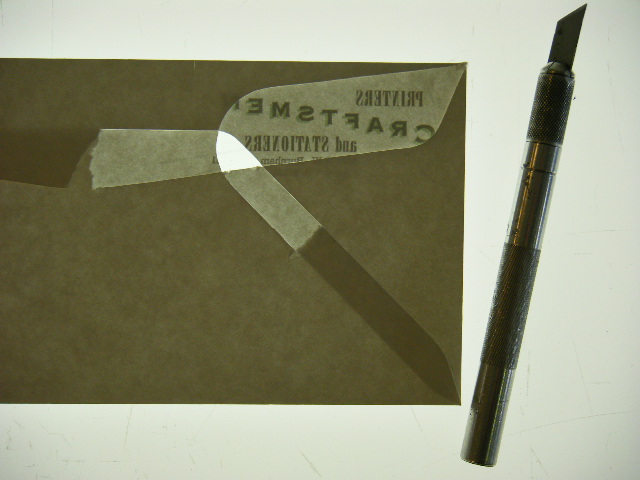

Envelope Makeready

If held to the light, an ordinary envelope will show areas of two, three,

and four layers of paper. If the printing spans different thicknesses,

an envelope makeready should be cut:

- Working as above, pull an impression on the envelope and stab through

it to be able to position it against the draw sheet beneath the tympan.

- Against a light table or window pane, working at first from the face

of the envelope, cut away entirely that small roughly triangular area

of the envelope that is four layers thick, where the front, flap, side,

and bottom panels overlap.This will scratch the glass. An art

knife may be used, but a wider, more chisel-pointed knife may be better.

The apprentice made his own makeready knife out of a piece of broken

hacksaw blade, sharpening the broken one-half-inch edge to make an

angle of about 70° with the length of the blade.

- Now, working from the back of the envelope, cut away two layers only

where three layers overlap. There are three such areas, radiating

outwards from the first cut in a sort of “Y” shape.

- Position this makeready under the tympan against the draw sheet, in

register with the job, using the stab marks. Move two or three packing

sheets from behind the draw to cover the makeready. This is done to

generalize the effect of the makeready since the envelopes will vary

somewhat in the position of their overlaps from conversion. If the

makeready has increased the thickness of the packing too much,

adjust the packing.

- When envelopes are fed to this makeready, all thicknesses will be four

layers. Where the fed envelope has four layers, the makeready has

none; where the fed envelope has three layers, the makeready has one;

where the fed envelope has two layers, so does the makeready.

- Ordinarily, the flaps of the envelopes are not opened for printing,

but sometimes it is better to open them, and to change the makeready

accordingly.

Scoring

Scoring against a die-cutting jacket, get position with a

perforating rule. Then replace it in the form with the scoring rule.

Check the squareness of a score with respect to the edge of

the sheet fed to the two bottom guides, since they can be moved to make

the score parallel or perpendicular to that edge. This means that a

score parallel to the edge is checked, not by folding on the score,

but across it, to see if the ends of the score meet when the ends of

the guide edge of the sheet are aligned. The outside of the

sheet faces the rule; the inside faces the matrix.

Home.